BUILDING DURABLE AND SUSTAINABLE INFRASTRUCTURE FROM WIND TURBINE BLADES

↓

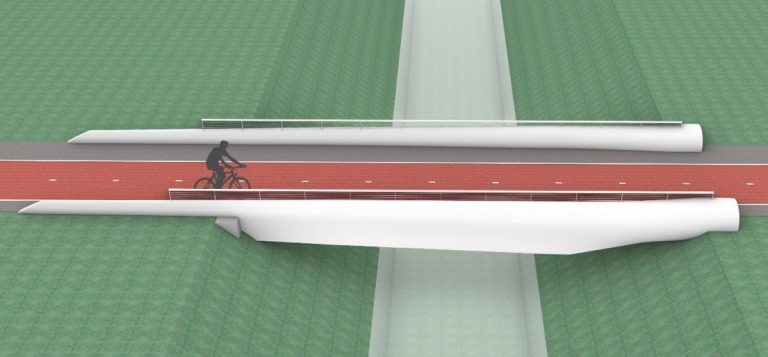

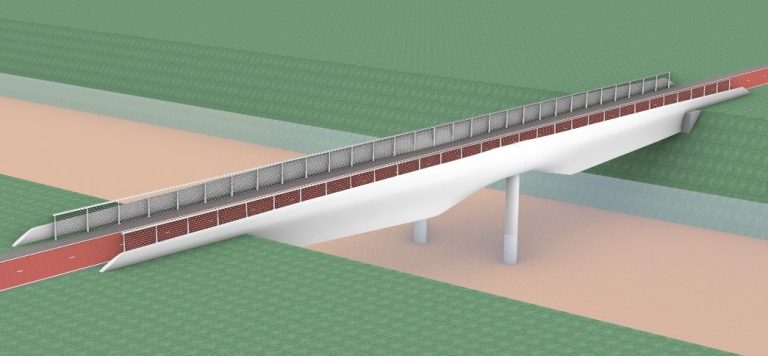

Bridges of Blades

When wind turbines are decommissioned, the blades still have excellent material properties. By structurally repurposing these blades, we strive to build circular bridges that are strong, stylish and sustainable. In this way, CO2 emissions and costs from both the wind industry and the infrastructure sector can be reduced.

Strong

The main material in wind turbine blades is glass fibre reinforced polymer (GFRP) composite, commonly known as 'fibreglass'. This material is stronger than steel and is extremely durable. Research shows that the blades still have excellent structural properties when decommissioned.

Stylish

The curved and tapered shape of a wind turbine blade allows for various organical bridge designs. The position and orientation of the blade in the bridge can be chosen based on location-specific requirements, related to aesthetics, clearance and structural requirements.

Sustainable

The construction sector is in need for circular building materials to reduce emissions. Wind turbines are typically decommissioned after 20 to 25 years already and it is difficult to recycle the blades. By reusing the blades, both the construction sector and wind energy sector become more sustainable.

info@infrablades.com

We hebben je toestemming nodig om de vertalingen te laden

Om de inhoud van de website te vertalen gebruiken we een externe dienstverlener, die mogelijk gegevens over je activiteiten verzamelt. Lees het privacybeleid van de dienst en accepteer dit, om de vertalingen te bekijken.